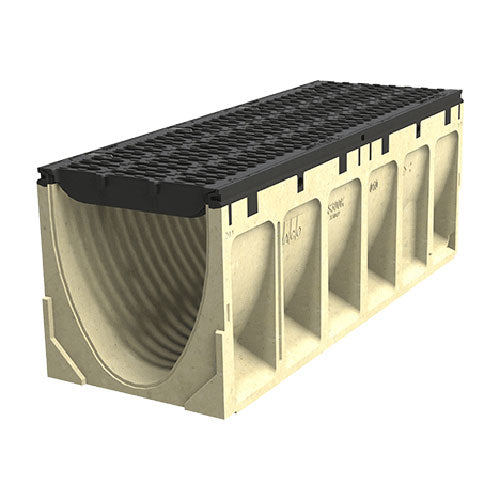

Heavy Duty Trench Drain System - 39.37" - ACO S300K

FREE SHIPPING

Engineered for the toughest industrial and commercial sites, the Heavy Duty Trench Drain System combines a polymer concrete channel with integral ductile iron rails to deliver exceptional durability, chemical resistance, and long service life.

Key Highlights

-

Extreme load capacity: Rated to EN 1433 Class F (proof loads up to 200,000 lb).

-

Efficient hydraulics: Built-in 0.5% slope and V-shaped invert accelerate flow and help self-clean the channel.

-

Secure grating: PowerLok® boltless locking with anti-shunt lugs prevents grate movement and rattling.

-

Modular flexibility: Mix sloped and neutral channels in multiple lengths; knock-out outlets simplify connections.

-

Faster installation: Numbered channels and optional installation aids streamline layout, grading, and setup.

System Selection:

-

Scroll down to select your system components. Multiple channel units are connected together and then paired with accessories such as catch basins and grates.

Please Use the Order Form Below to Order ▼