Pre Sloped Trench Drain System - 39.37" Channel - ACO K100

FREE SHIPPING

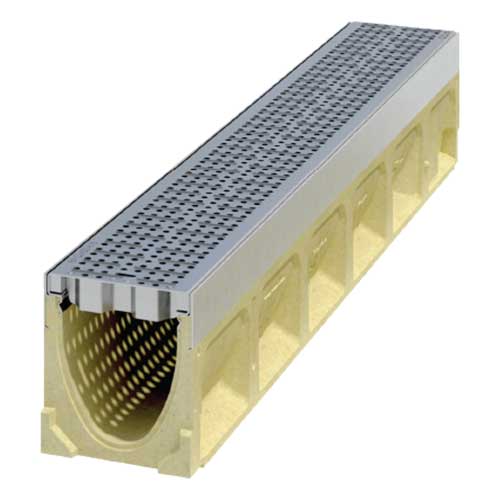

The ACO K100 Pre-Sloped Trench Drain System is a modular drainage solution engineered for efficient water management across a wide range of applications. With a 4-inch internal width and a built-in continuous slope of up to 130 feet, it ensures smooth water flow while reducing the risk of standing water. Constructed with durable galvanized steel or stainless steel edge rails, this system is designed for long-lasting strength and reliability.

Its innovative boltless locking mechanisms, DrainLok and QuickLok®, allow for quick, secure installation and easy grate removal, streamlining maintenance. Anti-shunt lugs and numbered channels further enhance performance by ensuring proper alignment and secure grate placement.

To meet diverse project needs, the system offers a broad selection of grate options—including mesh, slotted, perforated, and ductile iron—rated up to Load Class E for heavy-duty use.

System Selection:

-

Scroll down to select your system components. Multiple channel units are connected together and then paired with accessories such as catch basins and grates.

Note: ACO drainage products are subject to a $750 minimum order

Please Use the Order Form Below to Order ▼